From 2011 to 2015, Mingfa Tech has accumulated rich expertise of R&D in the field of LED cooling and works closely with professional partners in the high-end commercial lighting market. We have been recognized by the well-known LED partners such as Lumileds, Xicato, Bridgelux, Luminus, LG Innotek, Seoul Semiconductor and distributors around the world. We can provide fast feedback and fast delivery times. Mingfa Tech offers a full range of services, including cooling technology support, design consulting and manufacturing optimization. With our partner strengths in the PRD Economic Zone, we are well positioned to meet our customers' requirements for lighting kits in the optical and electronic applications.

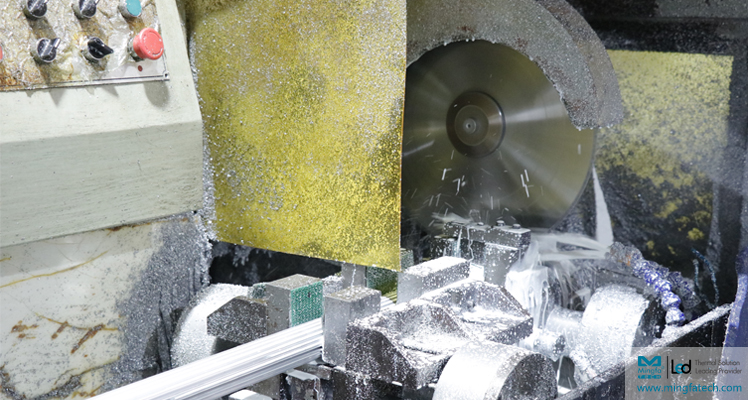

With the great mission of “making the luminaire look cool”, Mingfa Tech launched the GooLED cooler in early 2015 and introduced the xLED cooler in 2016. Both are made of high-purity aluminum material AL1070 with high thermal conductivity. All of these two series are passive coolers with very low power from 5W to 200W and no fans. They can be used for high bay lights. In addition, the two series are designed to be flexibly mounted with a variety of holes for easy assembly and operation of lighting components such as COBs, clips, brackets, and even for the fan of the cold forged LED heat sink products. Not only can we add custom holes to the base of the pin fin radiator, but we can also drill and tap on the blade side fins of the xLED cooler, which is a unique design in the cold forging manufacturing process of the lighting market. At the same time, xLED coolers with high-power heat dissipation are widely used in the development of LED plant growth lamps and mass production of horticultural lamps, which are better than expensive and low-security heat pipes or thermosiphons. Mingfa Tech offers designers and engineers a better and more viable option as well as an xLED cooling solution for plant growth lamps.

Mingfa Tech is expected to grow into one of the leading companies with great LED cooling solutions in the next three years. We are investing more in the research and development of new cooling products. In the fourth quarter of 2018, Mingfa Tech began the production of its newly designed FanLED cooler series, which offers more possibilities for optimizing lighting components such as hidden cables and drives in radiators, which can save space and improve the lighting design. It is often used for special applications. FanLED coolers are lightweight and their thermal efficiency is even higher than traditional LED heat sinks on the market. In the days to come, Mingfa will continue to focus on LED thermal management to create better and more revolutionary solutions for all customers.

sales@mingfatech.com

sales@mingfatech.com